How to Become an FEA Engineer

SKILLABLE INDIA

What is FEA Engineering?

FEA engineering in the context of CAE (Computer-Aided Engineering) or as a design engineer involves using advanced simulation techniques to analyze and optimize designs. As a design engineer, FEA engineering allows you to evaluate the structural, thermal, and fluid flow behavior of a product or system without relying solely on physical testing. By creating a virtual model and dividing it into smaller finite elements, FEA engineers can simulate real-world operating conditions and accurately predict how the design will perform. This enables you to identify potential design flaws, optimize material selection, assess structural integrity, and make data-driven design decisions early in the product development process. FEA engineering empowers design engineers to iterate and refine designs more efficiently, reducing the need for costly prototypes and extensive physical testing. It plays a crucial role in CAE workflows, providing valuable insights to improve the performance, reliability, and safety of designs across various industries, including automotive, aerospace, consumer products, and industrial equipment.

Responsibilities of an FEA Engineer

The responsibilities of an FEA (Finite Element Analysis) engineer can vary depending on the specific industry and company. However, here is a general outline of the step-by-step responsibilities typically associated with the role:

Understand project requirements: The FEA engineer begins by comprehending the project objectives, including the desired performance, constraints, and specifications.

Define simulation parameters: Based on the project requirements, the engineer establishes the appropriate simulation parameters, such as material properties, loads, boundary conditions, and analysis type (static, dynamic, thermal, etc.).

Model creation: The engineer develops a computer-aided design (CAD) model of the system or component to be analyzed. This involves creating a geometric representation of the object in specialized software.

Mesh generation: The CAD model is divided into smaller finite elements through meshing. The engineer generates an appropriate mesh to ensure accuracy while balancing computational resources.

Apply loads and boundary conditions: The engineer defines the external forces, pressures, temperatures, or constraints that the system will experience during operation. These loads and boundary conditions are applied to the model.

Material properties assignment: The engineer assigns appropriate material properties to each finite element, considering factors such as elasticity, thermal conductivity, and density.

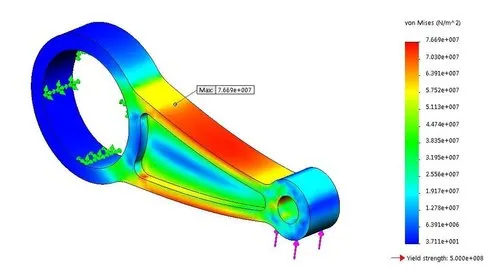

Run the simulation: With the model prepared and all parameters set, the engineer runs the FEA simulation using software tools. The simulation calculates and predicts the behavior of the system, such as stress distribution, deformation, heat transfer, or fluid flow.

Results analysis: After the simulation is complete, the engineer analyzes the results, interpreting the data to gain insights into the system’s performance. This involves examining stress concentrations, displacement, safety factors, and other relevant output parameters.

Report and documentation: The engineer documents the simulation setup, methodology, and findings in a comprehensive report. This report may include visualizations, graphs, and recommendations for design improvements or optimizations.

Iterative design improvements: Based on the simulation results, the engineer collaborates with the design team to refine the design, make necessary modifications, and ensure that the product meets the required specifications and performance goals.

Validation and verification: The engineer may compare the simulation results with physical testing or empirical data to validate and verify the accuracy of the FEA analysis.

Continuous learning and improvement: FEA engineers stay updated with the latest advancements in simulation techniques, software tools, and industry practices. They continuously improve their skills and knowledge to provide more accurate and efficient analyses.

How to Start The Journey to Become an FEA Engineer?

Usually, as mechanical engineers, you will need to be aware of FEA and CAE. You’ll also need to be familiar with popular FEA software like ANSYS and HyperMesh. Make sure to learn as much about this software at the college itself.

Outside of college, you must undergo an FEA engineer course to help ensure that you’re job ready. The minimum knowledge that you must possess is as follows,

- You’ll need to learn to identify the purpose of using FEA in the design process.

- You’ll need to avoid errors inherent to the FEA process.

- You’ll need to analyze the pros and cons of using different FEA methods.

- You’ll need to avoid common mistakes during the FEA process.

- You’ll need to consistently provide reliable results on time.

- You’ll need to interpret and make changes in the design accordingly.

- You’ll need to ensure an effective approach to managing FEA.

- Most of all, you’ll need to learn how to be cost-effective while ensuring the quality of FEA projects.

This is where Skillable India comes in. It offers several courses on FEA that will make you job-ready.

Are you starting as an FEA Engineer?

Confused about where to start as an FEA Engineer? Why don’t you check out Skillable India comprehensive list of PG Programs that will help you take your career to the next level?

There are multiple options: CAE, Design for Crashworthiness and Analysis, Hybrid Electrical Vehicle Design and Analysis, Automation & Pre-Processing for FEA & CFD Analysis, Computational Design and Pre-processing, and others that are some of the most in-demand courses in today’s world.

These courses will give you an in-depth understanding of what FEA is, how to perform Finite Element analysis, and learn software like LS-DYNA, allowing you to operate these programs at their full capacity.

These dynamic courses are not available for students during their UG courses, so they do not get to learn about these courses much. With Skillable India PG program, you can now access multiple courses and get into the depth of various subject matters.

With the help of these courses, you’ll be able to deal with complex industrial problems and gain industry-related best practices.

Book a Free Demo, now!

Know more about our Engineering courses with Job Assistance!